SOLO RESOURCE RECOVERY

Investing in Waste Collection Innovation Since 1932

The successful expansion of the company has been largely based on the decision taken in 1968.

Statistically we are now servicing over 1 Million bins per month nation wide, while at the Chinderah manufacturing facility, we have produced:

- 1116 Waste Collection Compactors

- 185 Front Lifts

- 12 Pump Trucks

Automated Side Loading Compactor

With the advent of ‘Wheelie Bins’ in 1980, the thought of automated collection immediately crossed our minds. So in conjunction with Mr Steve Guest (an operator in Leeton NSW) we developed automated collection of the wheeled bin…affectionately known as “MGB’s” (Mobile Garbage Bins).

The MGB was a German invention. They were smart enough to build to a universal standard. So having all the garbage bins of the same proportion, automation became comparatively simple.

On the other hand, the Americans decided to make 20 different style of MGB’s which precluded them from automated collection.

JJR automated collection started in earnest in 1985 and in 1986 we supplied collection vehicles to Blue Mountain City Council, making them probably the first council to introduce automated collection.

Fortunately for JJR we had long adopted side-loading as a principle means of collecting domestic waste whereas other manufacturers and contractors had gone the other way.

Our Chinderah factory is supported by other suppliers of elements of the finished product, including the fabrication of the main compacting paddle, manufactured exclusively in the J.R. Richards Tuncurry workshop.

Front Lift Compactor

Later illustrations of front-lifts will indicate the move to frameless construction once again. The scissor lift later gave way to a fixed arm design which is now the standard for the industry. The scissor lift had many operational advantages but the many working parts had long-term maintenance problems.

The original garbage collecting compactor designed and built in 1968 had far reaching and lasting affect on future operations.

Probably the largest manufacturer of waste handling equipment in Australia at the time,undertook a tour of Europe and America to ascertain in what direction garbage collection vehicles were heading for the future.

They concluded that the world-wide trend for garbage collection vehicles was to ‘Rear-Loading’. However, we remained committed to side-loading vehicles, having in mind that ultimate efficiency would be obtained with one man operating the collection vehicle (which of course was impossible with rear-loading vehicles).

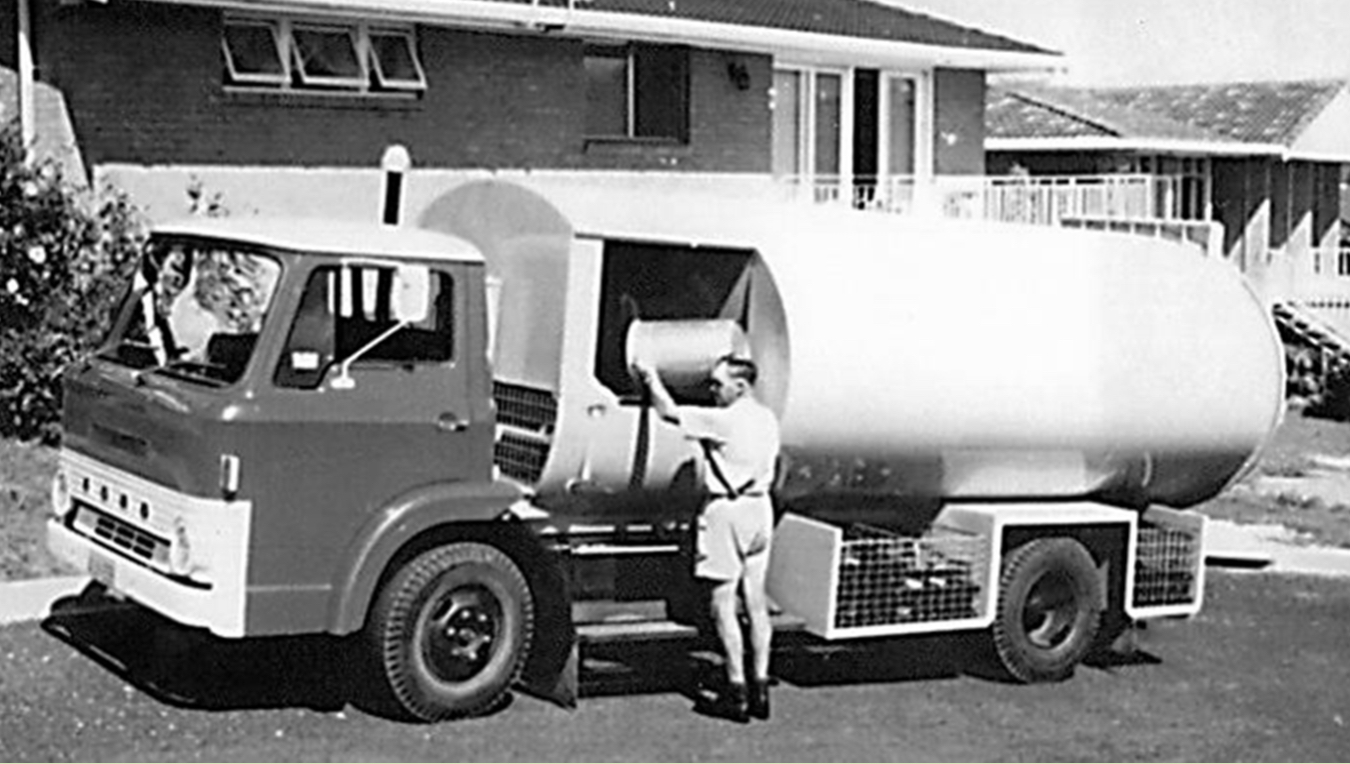

Utility Vehicle

A utility vehicle comprising a front loading mechanism, a side-loading mechanism, a compaction plate and a box on the rear door for the carrying of sanitary pans.

This unique vehicle was used to spread multiple services far and wide which singularly would not be affordable.

Front Lift Loader Compactor / Trade Waste Collection

In the 1970’s we built our first overhead loader which was described in the industry as ‘Scissor Lifting Arms’. Note that the body has copious external body framework to support the flat body panels. Last time this principle used in compactor body building.

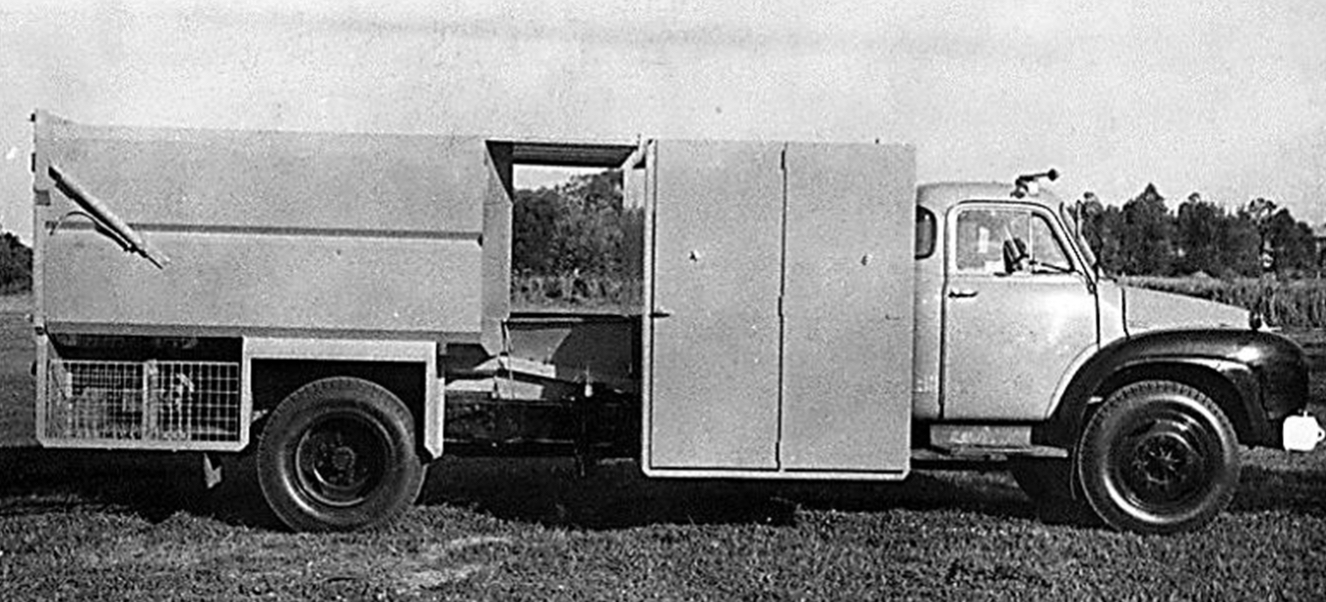

Combination Sanitary & Garbage Collection

As the need arose, various designs of collection vehicles evolved.

The vehicle illustrated provides sanitary pan storage in the front compartment, mini compactor in centre of the vehicle for acceptance of garbage & compacting into rear compartment.

Garbage Compactor Collection Vehicle

Idwall Richards went on to design and produce many variations to this original concept.

The image displays Jim Chippendale operating one of these units in Murwillumbah.

Garbage Compactor Collection Vehicle

It wasn’t until 1968 that the first garbage compactor collection vehicle was designed & built.

This mobile garbage compactor entailed a reciprocating packer plate (hydraulically driven) at the front of the vehicle. The packer plate simply moved backwards and forwards (approx. 700mm), and in so doing cleared the hopper quickly enabling frequent loading of garbage by hand.

This original packer was unique in that the body was of “frameless construction”, the designer (Idwall Richards) having reasoned that steel is extremely strong if kept in the tension mode as distinct from compression (bending).

This basic principle has applied to all our waste handling equipment for the ensuing 54 years.

The principle has been copied world-wide.

Garbage Covered Wagon

Come 1962 when JJR successfully tendered for the City of Toowoomba Sanitary & Garbage Contract, the most up-to-date garbage collection vehicles, all steel, with sliding covers were manufactured at Chinderah.

Workshop / Factory (Chinderah NSW)

The operation began in Murwillumbah at a specially developed facility for the disposal of night soil.

7 years later, with the expansion of sanitary and garbage services throughout the shire, the operation was moved to a disposal facility at Wommin Bay.

The move to steel bodies didn’t eventuate until post-war in the late 40’s on the return of Joseph Ronald Richards to the business after army service.

In 1950 a small workshop/factory was established on the Pacific Hwy at Chinderah where development of collection equipment really began.

Sanitary Truck

When JJR won the contract for the removal and disposal of night soil in the Municipality of Murwillumbah in 1932 (taking over Council operation utilising horse and cart for collection), he immediately moved to automobiles in the form of one new ‘International’ and one used ‘Dodge’.